DESIGN ENGINEERING

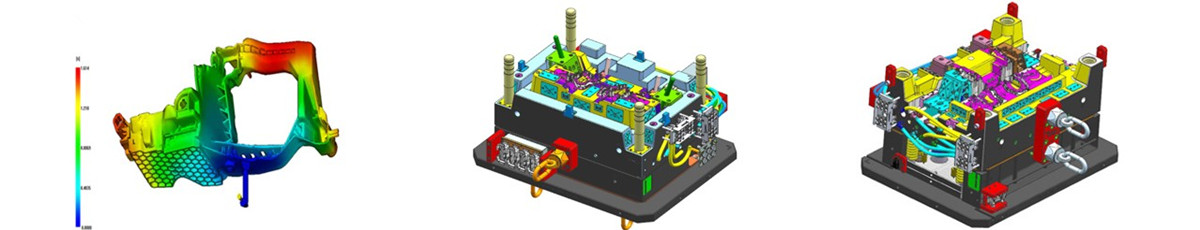

Being a leader in the plastic injection mould industry. We believe that a quality part comes from a quality mold and a good

part design, and a good mould design is the key to get a high performance mould.

Quality must begin with mould design capability and consider it to be the key to successful mould making.

At Heran Mold we have invested in both professional people and technology every year to ensure

that our designs meet your highest expectations.

Heran Mold is able to design mould according to customer’s product designs, 2D/3D models or drawings with specification. Our design capability include:

√ Convert Concept to Tooling Friendly 3D Model

√ ProductMoldability Study

√ DFM&Mold flow analysis

√ Full 2D & 3D mold design

√ Mold design optimization

√ Mold Manufacturability Analysis

√ Production Automation Development

√ Reverse engineering

√ Collaborative design with customer’s idea to improve

Our mould design is not just simply follow the customer opinion, but also based on the complexity of the mould. With over 10 years experience combined in plastics manufacturing, we are able to reveal potential quality problems or risks at the early stage, and in conjunction with the customer optimize the design to eliminate them before mould production starts.

The professional software used at Heran: √ Mould design software: AutoCAD, UG

√ Programming software: Powermill

Data exchange: UG, PRO/E, SOLIDWORKS, CAITA, CAD, STP, X_T, IGS, PRT, DWG, DXF, PDF, etc.